how blind rivets work

All blind fasteners are the same You can access blind fasteners from either side Blind fasteners are removable Any blind rivet will do Any blind fastener vendor will have what you need. Answer 0 Answer.

What Is Structural Blind Rivet Lituo Fasteners Manufacturer

How do blind rivets work.

. A structural blind rivet is a one-piece fastener made from two assembled components. Then a tool pulls the mandrel against the hat of the rivet. The back of the mandrel either has a bulge on the end or is connected to the hat in some way which makes the edges of the hat expand down towards the material.

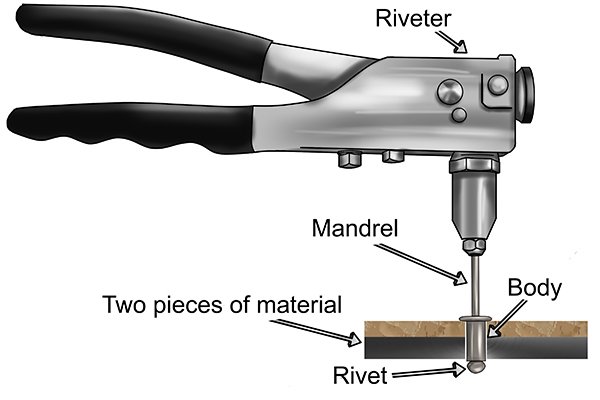

Plastic rivets suppliermetal rivets manufacturersteel rivets factorycustom brass rivetsaluminum rivets companyblind rivet wholesale. A pop rivet gun is placed on the rivet pulling the mandrel into the rivet body causing it to expand and grip the parts to be joined. A special pop rivet gun or tool pulls the mandrel head into the body of the rivet which then expands against the blind side of the join.

A pop rivet can be used as a replacement for nuts and bolts screws welds and adhesives. Common misconceptions about how blind rivets work. Blind rivets are used to connect thin plates tubes pipes and hinges among other things.

To use a blind rivet a hole is drilled then the rivet is seated inside of the hole. Applications and Types of Blind Rivets. Installation of blind rivets is easy.

Blind rivets can be used with both thin and thicker material. Then a tool pulls the mandrel against the hat of the rivet. Unlike a lockbolt or standard nut and bolt they can be installed with access to only one side of the material.

They can be set at 150 to 500hr and each setting is identical. The jaws retract extracting the mandrel which pulls. Once it meets the face of the joins blind side the mandrel snaps causing the stem to eject to create a tight joint.

The Blind Rivet tool is placed over the mandrel. At a predetermined point the exposed mandrel will. As the mandrel is pulled back it deforms the rivet pushing the sides outward until the mandrel snaps Step 4.

This means its possible to install them from one side or into a blind hole. Blind rivets are still increasing. This cuts assembly time.

3 set the rivet by pulling on the mandrel which creates a bulge that permanently and securely fastens the items. Blind rivets are installed in a tight hole that passes through the materials being riveted Step 1 2. A riveter is then used to pull the mandrel back while holding the rivet in place.

Once the rivet is in place the installer presses the trigger which pops the fastener into place by the force of compressed air. During installation blind rivets are inserted through a hole using a riveting tool. The rivet is first placed into an installation tool and is then inserted into the application.

The connection mechanically connects two or more plates. Activating the tool pulls the rivets mandrel drawing the mandrel head into the blind-end of the rivet body. Once gripped the mandrel snaps permanently holding the rivet in place.

A pin and a sleeve which delivers a permanent vibration-resistant joint in which the pin is retained post-installation for greater strength. This results in a localised joint. Activating the tool pulls the rivets mandrel drawing the mandrel head into the blind-end of the rivet body.

The Blind Rivet body is inserted in a hole in the materials to be joined. What is used to make leather. Can you pop rivet leather.

2 insert the mandrel into the special installation tool. These two components are. The stem is then released from the body leaving behind the expanded body to fasten the parts together.

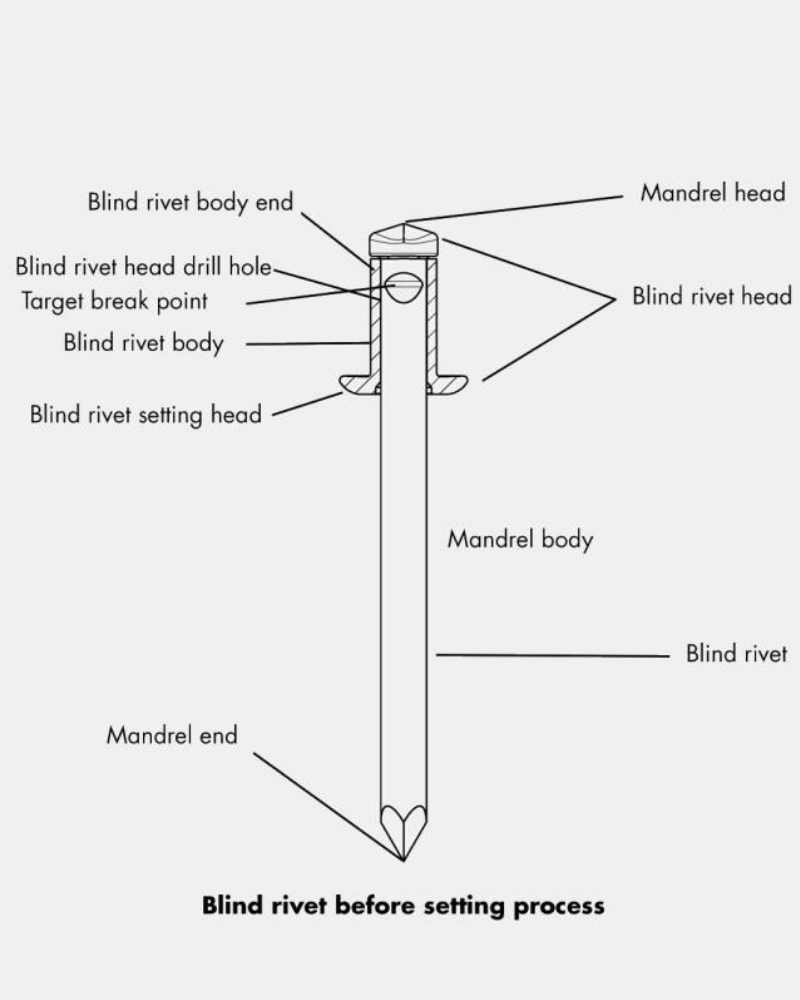

The back of the mandrel either has a bulge on the end or is connected to the hat in some way which makes the edges of. HOW BLIND RIVETS WORK The standard blind break-mandrel rivet is comprised of two components a rivet body and mandrel. However special-purpose riveting tools are required to install blind rivets.

The blind rivet is a mechanical fastening element consisting of a bushing and a mandrel to be applied through a riveting toolBy placing the blind rivet into. To use a blind rivet a hole is drilled then the rivet is seated inside of the hole. As the mandrel is pulled back it deforms the rivet by pushing the sides outward until the mandrel snaps.

The rivet is first placed into an installation tool and is then inserted into the application. Blind rivets are hollow with a mandrel on a stem that runs through a central hole. The tool is actuated and the jaws of the tool grip the mandrel.

By drawing the mandrel back through the rivets body the factory head can be formed from the opposite side. Blind rivets are the fastest way to join materials. Comprised of a rivet and an integrated mandrel blind rivets are installed in a tight hole that passes through whatever material youre riveting.

How blind rivets work. The tail of the rivet compresses and locks the fastener into place. A riveter is used to pull the mandrel back while holding the rivet in place Step 3.

Vansha 15 Jan 0 Answer answer. There are different types of blind rivets but most of them consist of a body and a stem. How does a blind rivet work.

1 insert the rivet into a hole that passes through the items to be joined. This results in the body expanding while inside of the hole. The blind rivet is driven into a pre-drilled hole when the user places the fastener into place whether on the end of the driver or in the pre-drilled hole.

How Blind Rivets Work The standard blind break-mandrel rivet consists of two components a rivet body and mandrel.

How Does A Blind Rivet Work Wonkee Donkee Tools

What S The Difference Between The Rivet And Blind Rivet Lituo Fasteners Manufacturer

What Is Structural Blind Rivet Lituo Fasteners Manufacturer

What Is A Blind Pop Rivet Gesipa

What Is A Rivet How Is Riveting Done Riveting Definition Types Of Rivet In 2022 Rivet Threaded Fasteners Metal Pins

Tips For Tougher Blind Rivet Connections Goebel Fasteners

How Rivets Work Rivets Fasteners Screwdriver

State Enterprises Blind Rivets Riveting Tools Blinds Riveting

Benefits Of High Strength Structural Rivets Goebel Fasteners

What Is Structural Blind Rivet Lituo Fasteners Manufacturer

Blind Rivet Design Guide Hanson Rivet Design Guide Design Blinds

In This Video One Of Our Resident Fastener Specialists Talks About How You Can Remove Installed Pop Rivets Blind Rivets Are Considered Pop Drill Bits Rivets

Gauge Blind Rivets Rivets Blinds Rivet

How Do Blind Rivets Work Fastenerlab Supplier Advance Components

What Is Structural Blind Rivet Lituo Fasteners Manufacturer

Understanding Rivet Tools For Various Applications Goebel Fasteners

The Advantages Of Using Pop Blind Rivets Rivets Blinds Riveting Tools